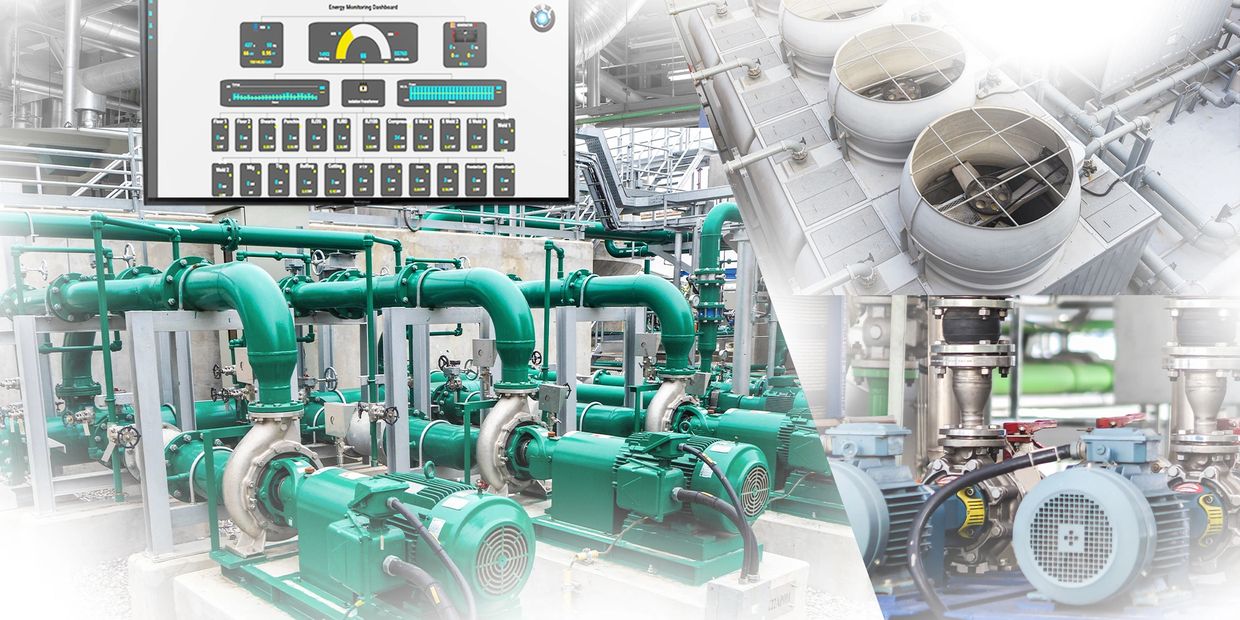

Shop Floor with Industry IoT Solution

Many manufacturers find it hard to identify those specific losses that contribute to low machine productivity as they are difficult to identify,record, and analyze,so manufacturers are looking for digitize day-to-day manufacturing processes & support in making the move toward smart factory transformation.Shop Floor AI 4.0 solution integrates multiple technologies in a layered architecture supporting IoT devices,secure networking and Intelligent Applications that allow to achieve overall equipment effectiveness and improve the shop floor visibility & performance.

Digitally Transform your Shop Floor

- Unlock Hidden Production Capacity

- Minimize Unplanned Down time

- Shorten Production Lead Time

- Increase Machine Availability

Start Your Shop Floor AI 4.0 Journey Today!

Data Acquisition

Data acquisition (DAQ), data logging and controlling the operational status of facilities such as on/off status, pressure and temperature,Vibration , Energy ,IoT & communication gateway for latest PLC and legacy systems goes through the OEE edge into one single platform.

Digitize & Visualization

Provide insight into prevailing conditions on the Production Floor. Ingests and process data from multiple sensors to deliver actionable intelligent reports . Enable management of large work force with minimal Technical expertise.

Analyze & Transform

Shop Floor AI 4.0 defines a new way of transforming factories into smart / intelligent factories for efficient and easy remote monitoring of machines and its processes .Enabled with Preventive Analytics using Machine Learning reduces downtime and improves efficiency

To Know More, CLICK HERE,

.png/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:365,h:274.4360902255639,cg:true)