The majority of manufacturers want to install Energy Management Systems in their factories to reduce energy consumption , predict failures and identify root cause abnormalities. EMS Platform allows users to monitor energy consumption information, accurately evaluate energy costs, and optimize energy efficiency by 8-10%.

- Centralized monitoring with automatic pre-warning Alarm

- Real-time End to end traceability of consumption

- Centralised monitoring with automatic pre-warning Alarm

- Visibility of utilization of utilities and track them to set baseline values saving from penalties

- Improve stand-by operation & energy cost per unit

- Eliminate routine waste & reduce energy cost

- Proactive alerts of failure and disturbances

- Enable management with KPI views to set Utility Goals

- Reduction of production costs and Energy Efficiency

- Early detection of potential problems leads to increased uptime Maintenance activities , improved Safety and longer machine lifespan.

- Minimize Unplanned Downtime and reduce the maintenance costs & time.

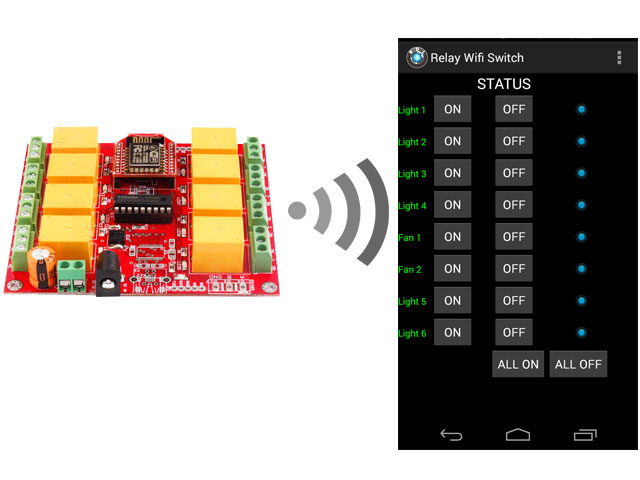

- Remote & real-time monitoring system helps in achieving high operation efficiency

- Chances for human error, Not 100% Accurate readings noted and Only Specific Parameters are Captured

- Energy utilization analysis performed using Excel based tools, lack of scalability and is unable to manage complexity.

- Lack of data processing capability and required huge volumes of redundant data to be stored and maintained.

- Limited visualization only provided localized view of the system

- Invisibility of wastage, and any breakdown will lead long time to analyze

- Predicting the root cause and anomaly is not possible

- There are no proactive failure and disturbance alarms.

.jpg)

.jpg)