Remote Condition Monitoring System

Condition Monitoring - Increased Reliability

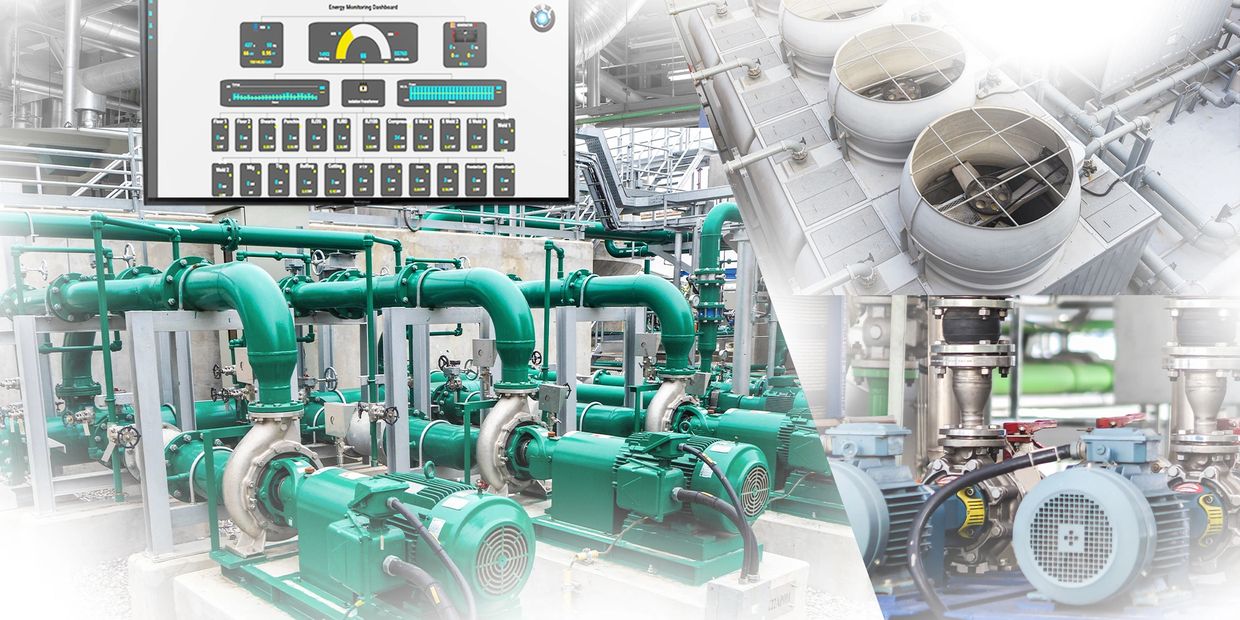

Remote condition monitoring solution ideal for motors that play a critical role in production and sensitive applications.Operators can use Condition Monitoring System for remotely monitor the health, performance, and efficiency of the motors, as well as detect early signs of potential problems and schedule maintenance so that a fixable problem does not worsen and cause unplanned downtime.

Advantages of Condition Monitoring

- Proactive alerts of potential problems reduces down time

- Minimize Unplanned Downtime and reduce the maintenance costs & time.

- Condition-based maintenance leads to increased reliability, improved up time

- Early detection of potential problems leads to increased up time Maintenance activities , improved Safety and longer motor lifespan.

- Remote & real-time monitoring system helps in achieving high operation efficiency

What is condition monitoring?

Machines and systems are carefully observed for changes that could indicate upcoming failure.The sensor data is analyzed to determine that could affect the functioning , like Temperature ,Vibration , Speed , Energy consumption ,suction and discharge pressure has changed while it is in operation .

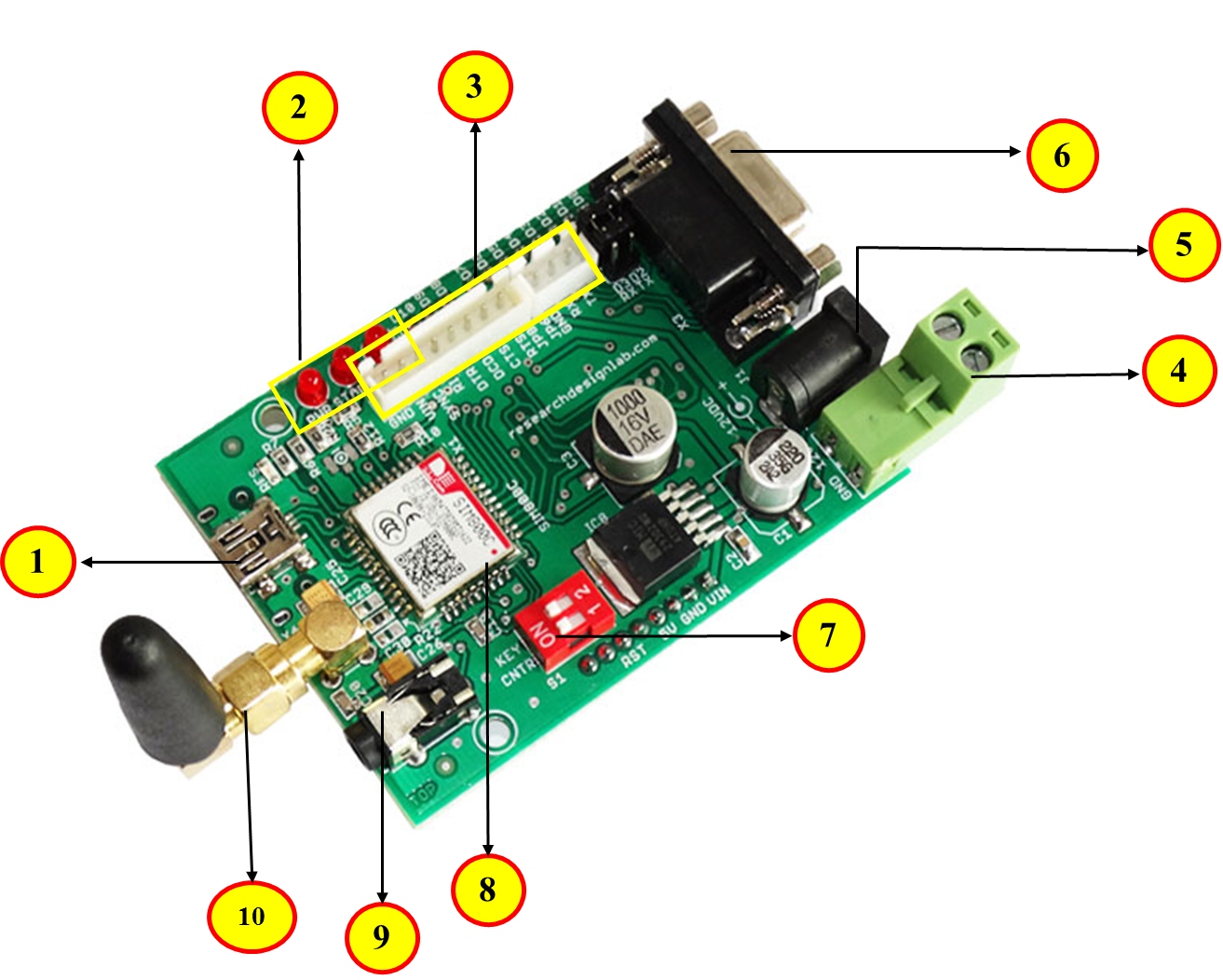

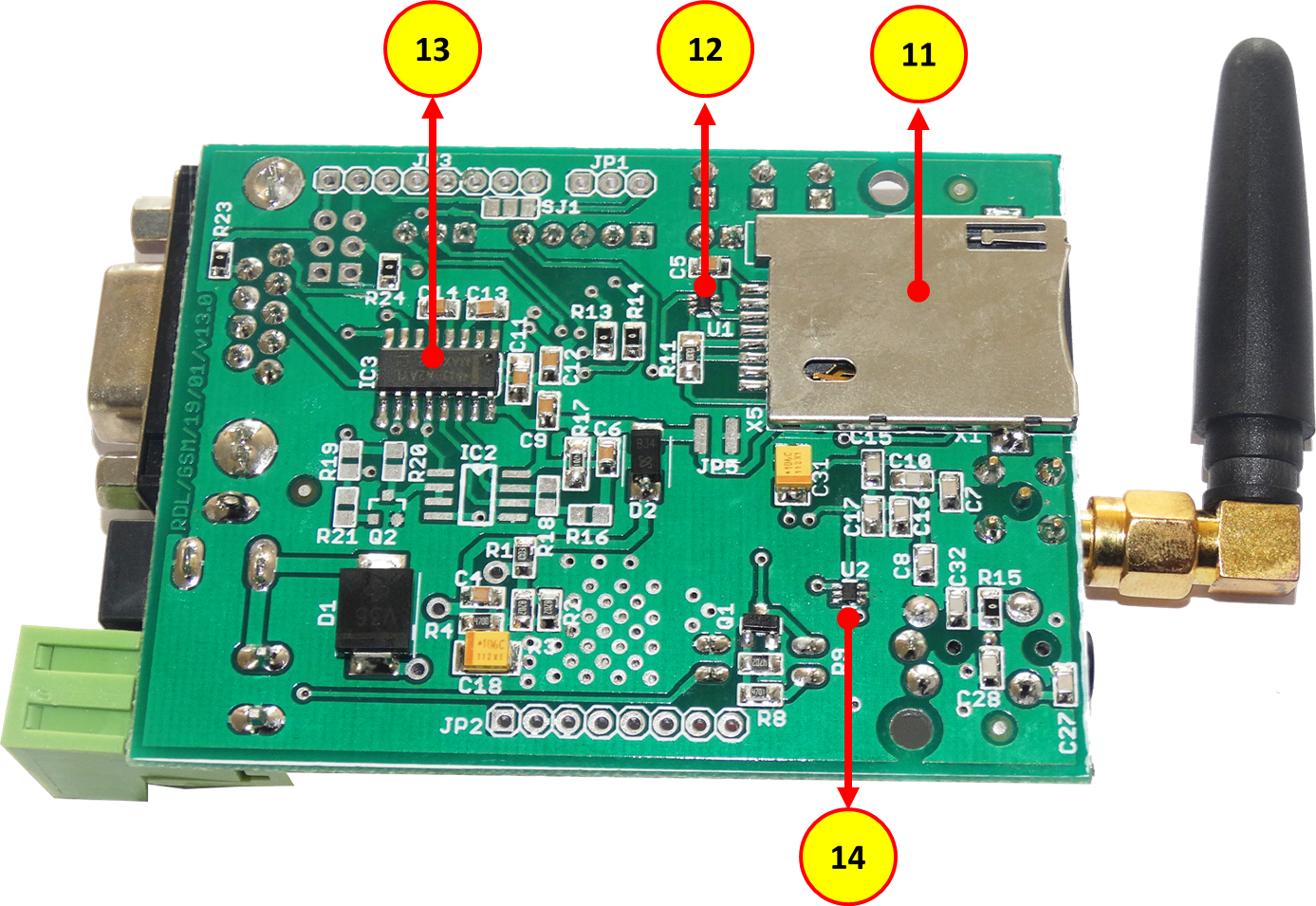

Remote Condition Monitoring System Architecture

Most Advanced and Intensive Type of Maintenance

Transform your factory to Condition based - Predictive Maintenance

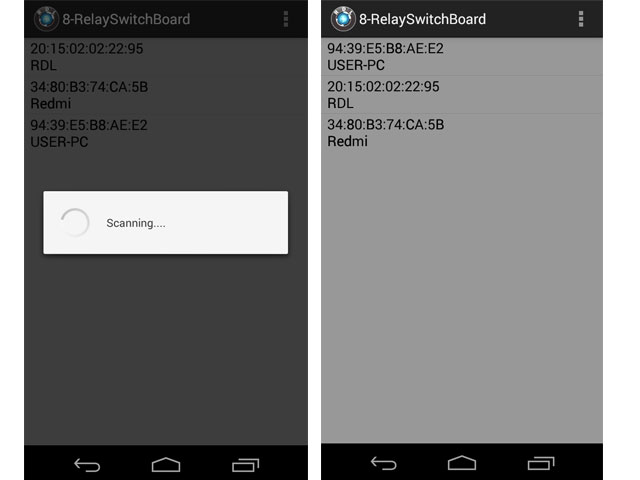

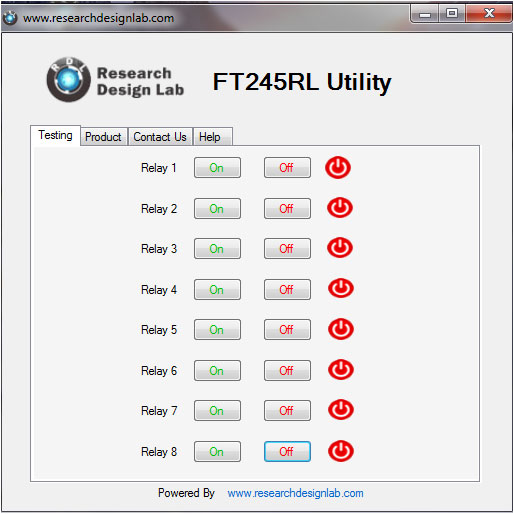

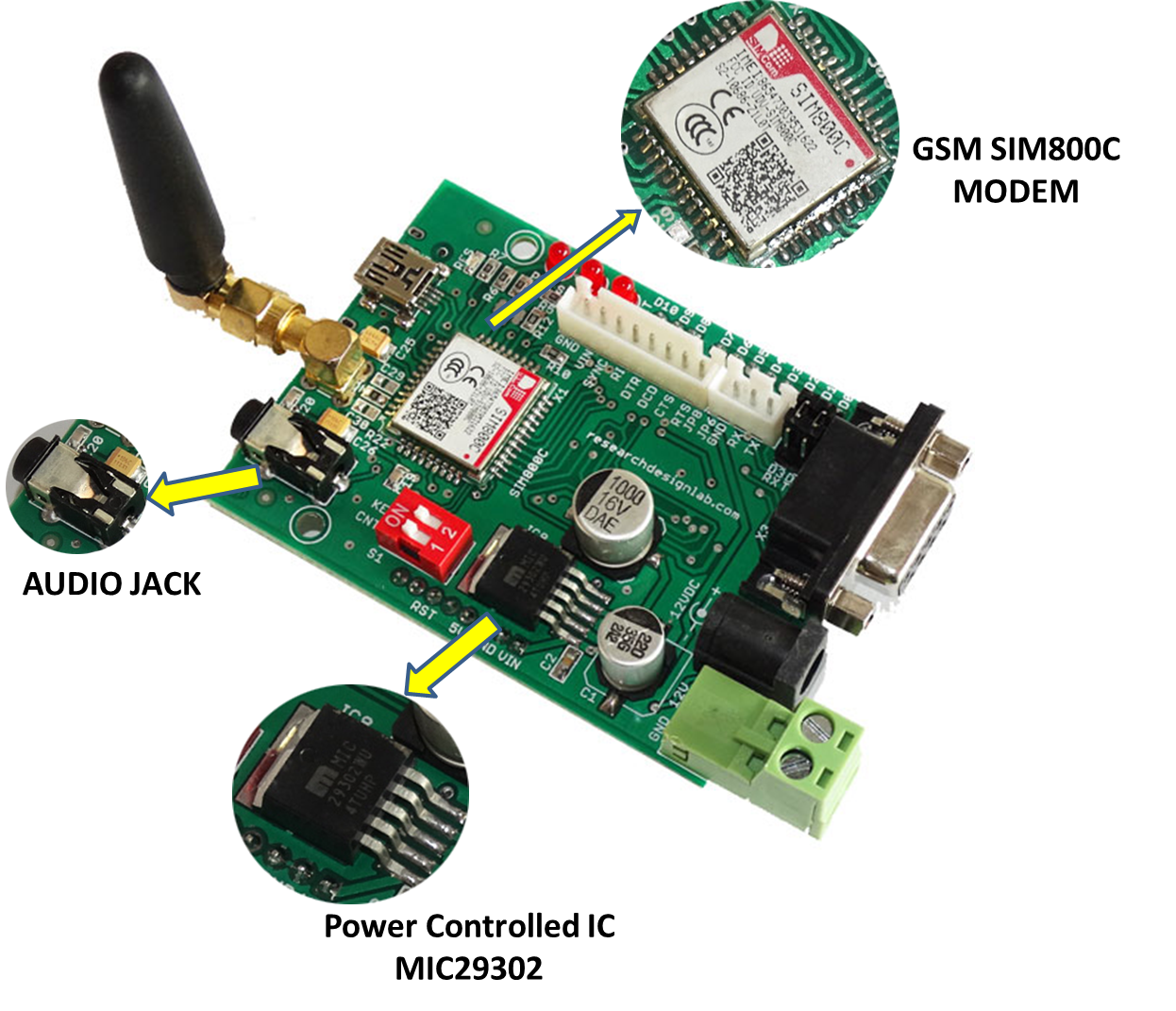

Predictive maintenance is generally considered to be the most advanced and intensive type of maintenance.Predictive maintenance is a type of condition-based maintenance in which systems are monitored continuously using sensor devices. Ingest and process data from multiple sensors to deliver actionable intelligent reports & alerts. System sends alerts as an email or SMS notification.

- Equipment status & data visualization dashboards

- System sends alerts as an email or sms notification.

- Application Software deployed in Local server / Cloud .

- Algorithms for vibration analysis FFT, Time Domain, RMS trend

- Real-time configurable Report

- Access Anytime Anywhere

- Error Trend Analysis

- MTTR & MTBF

.png/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:365,h:274.4360902255639,cg:true)